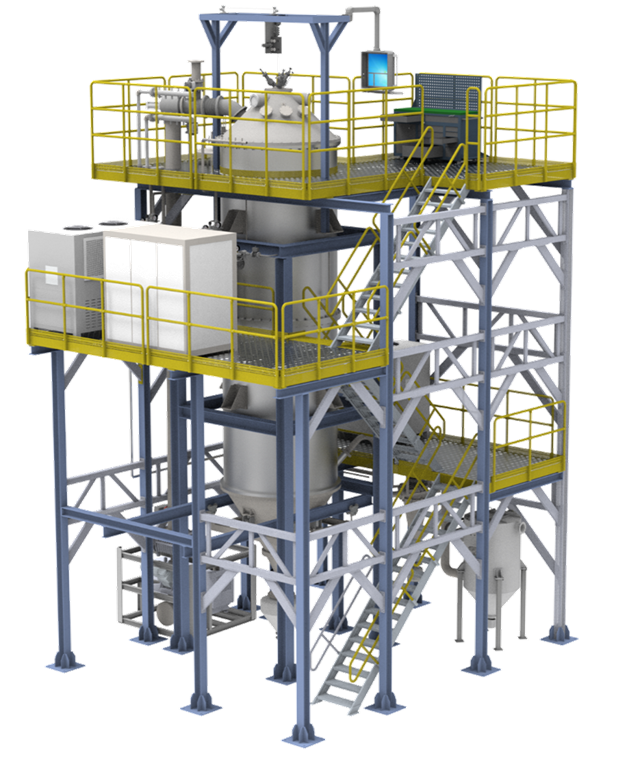

NHL PA150 supersonic plasma atomization powder making system adopts the plasma wire atomization powder making technology independently developed by Navector Laboratory. The technical principle is that the raw metal wire is produced by one or more plasma torches. The high-temperature and high-speed thermal plasma jet is simultaneously melted and atomized and broken into fine metal droplets, which are finally solidified and cooled into fine metal powder.

The new generation of plasma wire atomization powder making equipment independently designed and manufactured by Navector Laboratory New Additive Manufacturing Research Institute has broken the technical blockade of the United States and Canada. The equipment has both low cost, low doping and production capacity. With many advantages such as expansion, stable mass production of active metals such as titanium and vanadium and refractory metal powders such as tungsten and molybdenum can be realized.

|

Features |

Atomizing |

PA Tech |

|

|

COST |

Fine powder rate |

35-40% |

45-60% |

|

Air consumption |

1200m3/h |

20m3/h |

|

|

Gas Cost |

¥80-120/kg |

¥15-30/kg |

|

|

QUALITY |

Sphericity |

~0.9 |

>0.95 |

|

Hollow Powder |

More |

None |

|

|

Satellites |

More |

None |

|

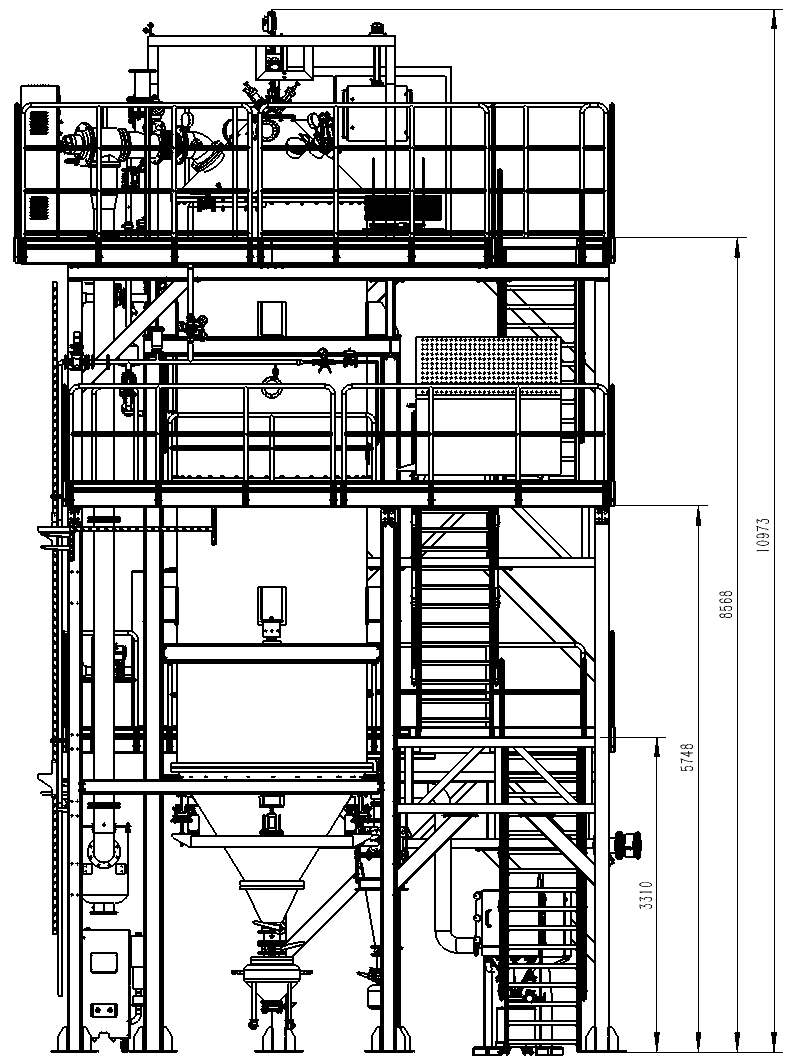

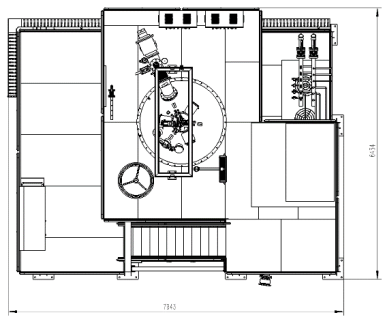

Main technical parameters:

|

Technical indicators |

Specific technical parameters |

|

Plasma torch specification |

3×50kW high-energy DC plasma torch (customizable) |

|

Nozzle type |

Supersonic LAVAL nozzle |

|

Plasma power supply |

IGBT DC power supply, three-in-one plasma power supply, continuously adjustable power |

|

Atomizing chamber vacuum |

≤1Pa |

|

Wire feeding speed |

5-50mm/s |

|

Wire feeding diameter |

1.6mm/2mm/2.5mm/3.2mm(customized on demand) |

|

Atomization efficiency |

3-8kg/h(based on TC4 titanium alloy) |

|

Support atomization materials |

Titanium alloys, high temperature alloys, refractory metals and alloys |

|

Atomizing tank |

304 stainless steel on both sides, polished inner wall |

|

Atomizing Gas |

Argon or Helium |

|

Powder sphericity |

>0.95 |

|

15-53μm yield |

≥45%(based on TC4 titanium alloy) |