Introduction

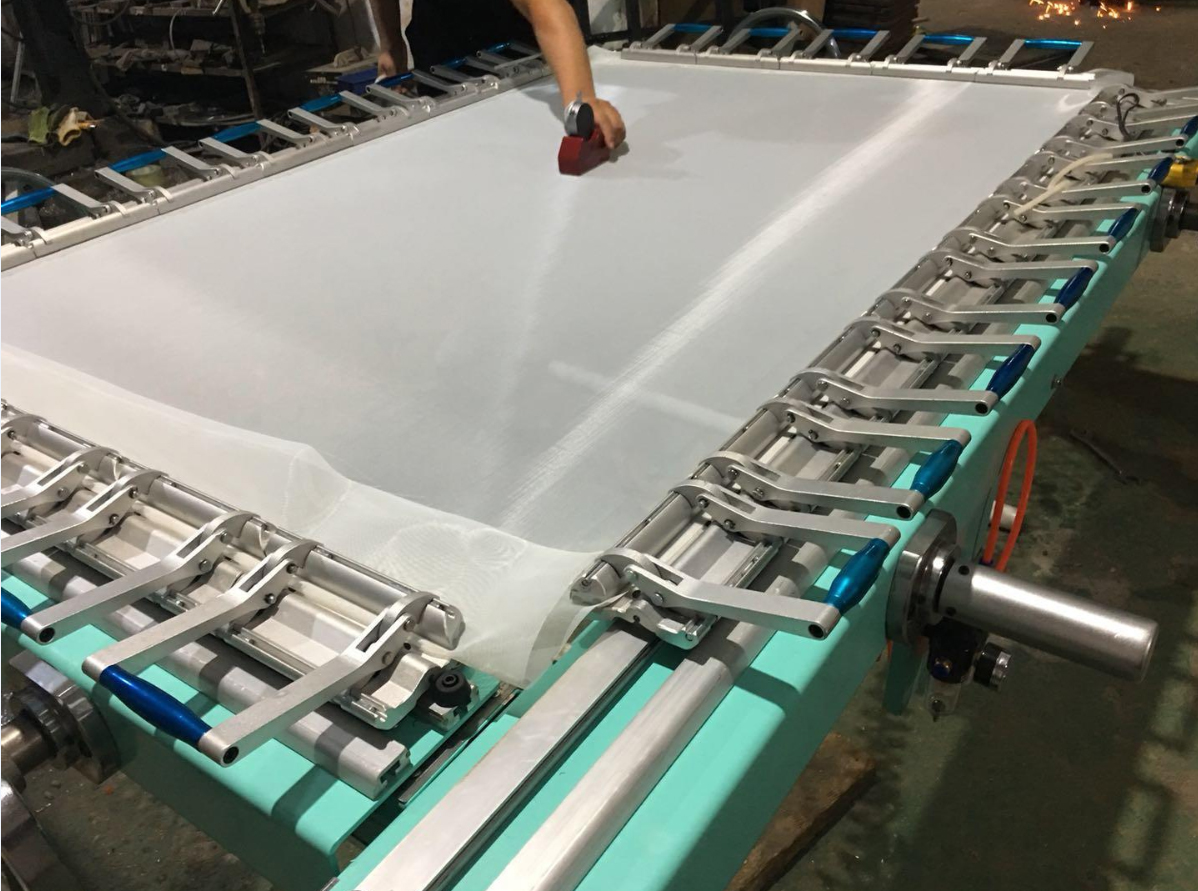

The designed tension table is for tensioning the wire mesh at suitable tension value with specified apeture size. Definitely, it will provide a more accurate and scientific method to repair a sieve frame before glue it.

This product is mainly used in the production of high-precision industries such as vibrating screens, medical treatment, and ultrasound.

Basic conditions

a. Environment

Site selection height: 40 meters above sea level

Temperature: 0-40℃

Air humidity: 70%

b. Electrical

Power supply voltage: 220V

Wire groove height: the bottom surface is 15cm from the ground

Processing

Standard machining part name: screen frame

Size: Maximum outer diameter of aluminum frame 1550*1800

Working hours: 24 hours/day, 7 days/week, 50 weeks/year

c. Equipment

Machine size (W × D × H): 2150mm × 2400mm × 760mm

Equipment color: green spray

Equipment characteristics

Comparision

|

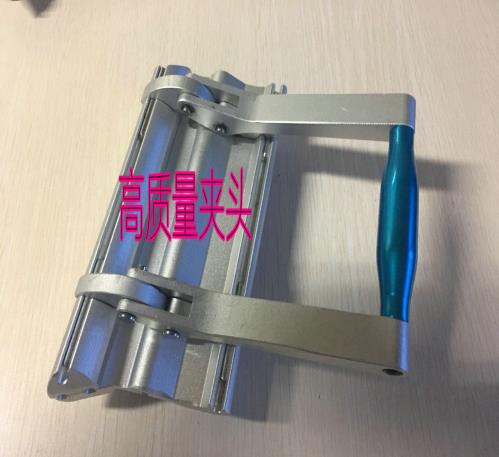

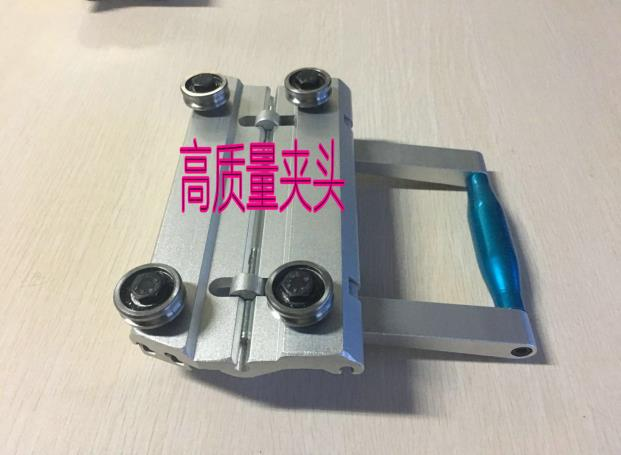

Description of high-precision Clamp: The template is the latest imported template, the highest standard of existing technology, the highest standard in the industry, the technology adopts wire cutting technology, precise size design, special customized carbonate steel bearings, strong endurance, durable and not easy to wear, and the cost is ordinary 10 times as much as the bearing. The inner lining is made of wear-resistant silicone material. The entire material of the clamp adopts one of the highest hardness in China, and the price of raw materials is twice as much as that of ordinary aluminum profiles. It is one of the necessary conditions for a high-demand machine. |

|

|

|

|

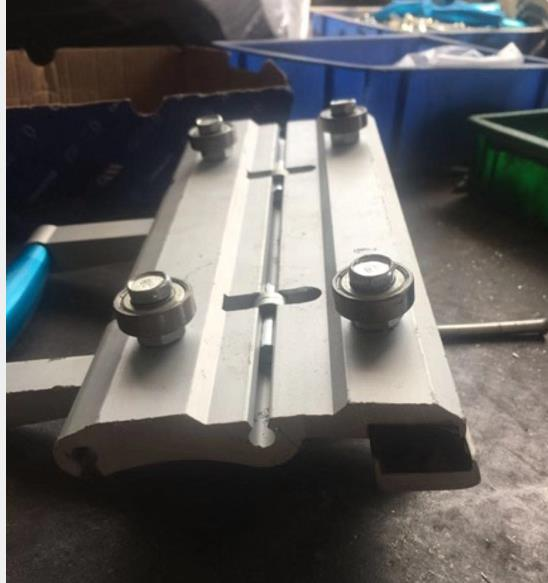

Description of common clamps in the market: The lining is rubber, which is easy to wear and is not durable. The cost is low. The bearing is made of ordinary iron sheet material. The cost is low. The template is a cutting machine process and the material is aluminum material. It is more suitable for general printing industry. |

|

|

|

Equipment specifications

Equipment List

Item

Model

Qty

Aluminum alloy double clamp

20#

34 pcs

Clinder

45*70MM

4pcs

Casters

3" universal

4pcs

Handwheel

250MM

4pcs

Barometer

0-6MPA

1 pc

Aluminum main beam

60*100MM

4pcs

Support frame

2000*2000MM

1 PC

Support plank

1.7*1.5 Meters

1 PC